ITAC employ a variety of testing methods to develop adhesive coating products that align with their customer’s application requirements. This area of work ensures reliability and uniformity in the bonding process within parameters that may also influence performance including consistency of raw materials, application substrates, environmental conditions, and joint design. The results of these tests support the customer to choose the best adhesive coating system for a specific application and helps optimise the formulation process to ensure product specifications are achieved. The business has now expanded its testing capacity to include flammability testing for fire retardant coating materials.

Flammability testing is an essential part of ensuring the fire safety of the public at large and end-product users. Flammability testing can also limit the risk to manufacturers from regulatory authorities taking action against them due to failure to comply with relevant standards. Although figures have come down in recent years, the UK Home Office still reported 316 fire-related deaths resulting from 36,283 dwelling fires in 2019. This, together with the Grenfell tower fire tragedy in 2017, has placed a razor-sharp focus on the requirements for establishing minimum flammability requirements for various materials and finished products.

Synthetic and natural polymers are generally flammable…

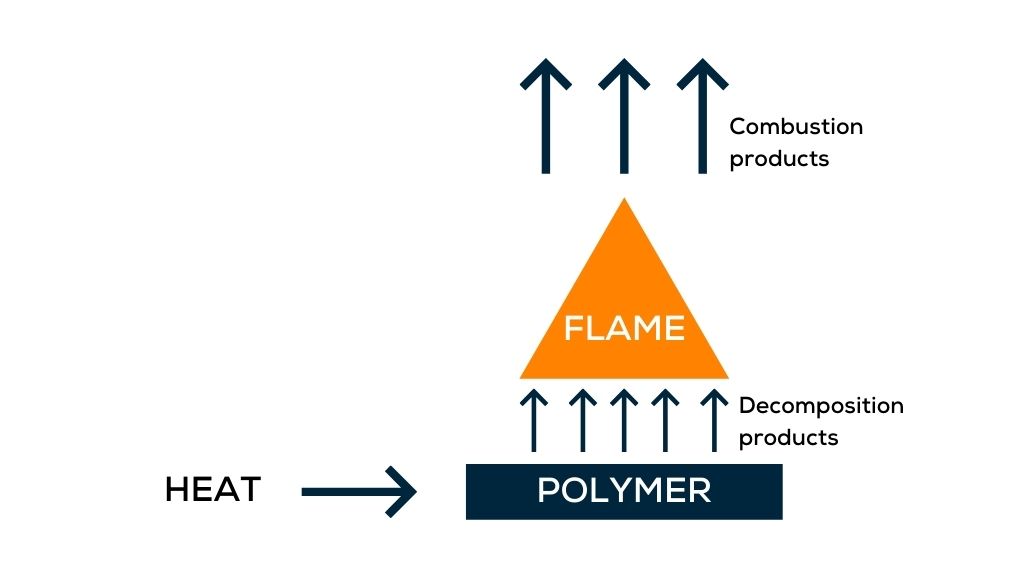

Much of the material making up our physical surroundings, and the everyday products we use, consist of polymers that are organic and hydrocarbon in their molecular nature. This renders them a good fuel for fire so makes them naturally flammable. In fact, as polymer structures increase in complexity, so does their reaction to combustion. For example, the polyurethanes in an array of products across multiple industries, suffer serious flammability issues, and experience rapid decomposition which releases large amounts of heat during combustion.

Diagram illustrating polymer combustion, condensed phase pyrolysis and smoke formation, adapted from Price, D., Anthony, G. & Carty, P., (2001), “Fire Retardant Materials 1–30”, cited in Elsevier, (2001)

With the UK producing 1.8 million tonnes of plastic materials alone per year, we have the major challenge of rendering these materials less flammable.

Improving flammability properties…

Fire retardant additives are commonly added to polymer materials to improve their flammability properties. These work to interrupt the cycle of combustion by altering the combustible substrate or fuel source, by lowering the heat of combustion to unsustainable levels, or by altering the oxidizing gas. Another chemical mechanism is the formation of a physical barrier to protect the polymeric substrate when it comes into contact with a source of ignition. The solid layer formed is carbonaceous and acts to push the flames away from direct contact with the substrate, whilst also helping to trap volatile gases that would otherwise serve as a fuel source. It is important to remember at this point that a fire retardant coating does not necessarily prevent fires; instead, their purpose is to slow down the rate of flame spread.

The flammability of a material defines how easily it will burn or ignite to cause fire or combustion. These characteristics are measured through flammability testing and several protocols are used to quantify a material or product’s susceptibility to ignition, tendency to combust, and the rate of flame spread once it is ignited. ITAC are capable of developing and testing a range of fire retardant coating formulations that reduce the flammability of a range of substrates. The resulting fire safety characteristics of substrates tested depends significantly on the coating formulation.

Flammability testing methods…

With their flammability chamber, ITAC use Federal Aviation Regulation (FAR) testing methods. These determine the resistance of material to flame over varying periods of time and across several different test geometries. They include vertical, horizontal and 45° flammability testing which provide information on different parameters such as flame time, drip time, burn length, burn rate, glow rate and flame penetration.

For further information on ITAC’s flammability testing capabilities contact Tyler Coleman, Technical Manager, on 01204 573736 or by email at TColeman@itac.uk.com.