Adhesives and coatings specifically for mounting, laminating, and encapsulating various types of signage and graphics media

Well designed and fitted signs, graphics and other display materials play an essential role in most industries. They ensure visibility of brands, products or services and have a significant influence on the way they are perceived. As the old sayings go; “first impressions count” and “a picture is worth a thousand words!”

Graphics are also used to communicate information in a clear and concise way. The desired message may have different purposes, for example, persuading, instructing, inspiring, educating or entertaining people. However, it is the physical clarity and appearance of these graphics that ensures messages and information are conveyed as intended.

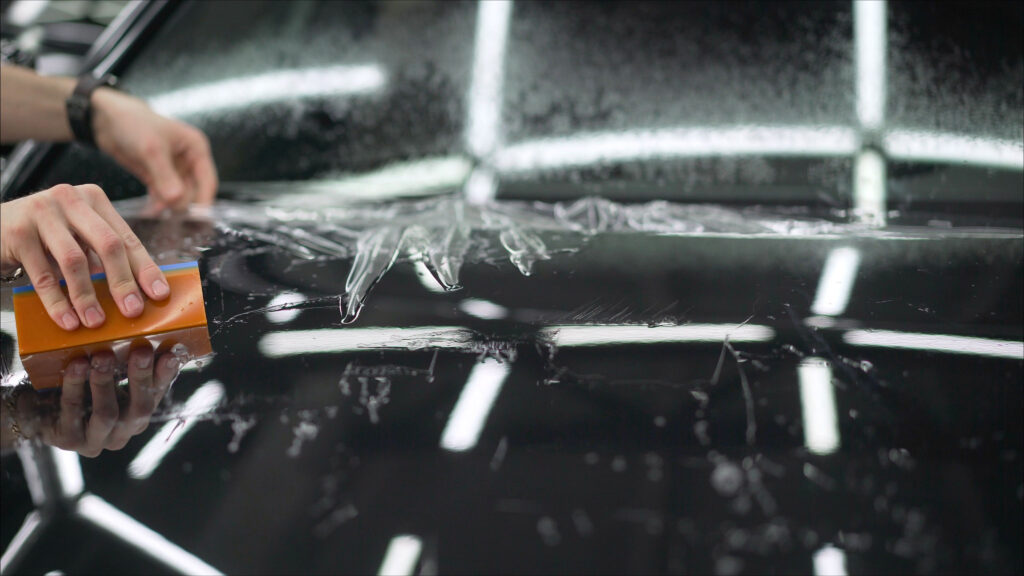

Itac have successfully formulated and developed a range of adhesives and coatings specifically for mounting, laminating, and encapsulating various types of signage and graphics media such as vehicle wraps, retail outlet window films, exhibition stands and displays.

From vehicle wrapping to fine art lamination, our adhesives and coatings have enabled uncompromised designs, better aesthetics, and lower costs in terms of application, installation, and maintenance.

Whether it be our pressure sensitive, heat activated and dry mounting adhesives, or our polyurethane based coatings; outstanding delivery and performance can be expected with every application.

How we do it

Our graphics range of solvent based adhesives and coatings are designed and manufactured specific to your display requirements. These may include removability, weathering capabilities and cohesion strength to different substrates.

Our lamination and encapsulation coatings protect signs and displays against scratches and other damage, enabling them to retain their original aesthetic appeal.

Itac recognise that one adhesive or coating does not do everything for everybody! Our technical team work hand-in-glove with designers and manufacturers to align the chemistry with the right application technique. By doing this, we ensure a truly bespoke compounding service for every application we are tasked with, backed by the trust and confidence our customers have put in us for over 100 years.

Applications:

• Vehicle wraps

• Window films

• Reflective products, eg, road signs

Benefits:

Applications:

• Film adhesive for large format window, wall, and floor graphics.

Benefits:

Applications:

• Artwork framing applications.

• Canvas or textured substrates.

Benefits:

Applications:

• Pressure sensitive tapes.

Benefits:

Applications:

• Printable textile coating for indoor banners, temporary outdoor banners, exhibition stands and displays, backdrops, and Point-of-Purchase retail signage.

Benefits:

We would be delighted to learn more about your product and project ideas. Complete this simple form or call us on 01204 573736.